Vidiyo

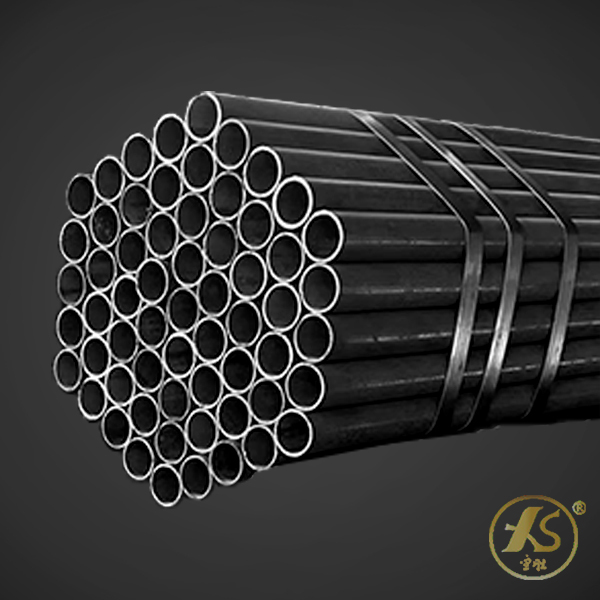

Ọkpụkpụ nchara na-enweghị nkebi maka mgbawa mmanụ ala

Usoro nrụpụta ngwaahịa

Tube oghere

Nyocha (nchọpụta spectral, nyocha elu na nyocha akụkụ)

Ịkwọ osisi

Perforation

Nyocha okpomọkụ (nchara alloy chọrọ ọgwụgwọ okpomọkụ)

pickling

Nnyocha egweri

mmanu mmanu

Ihe osise oyi

mmanu mmanu

Ihe osise oyi (mgbakwunye nke usoro cycled dị ka ọgwụgwọ okpomọkụ, pickling na eserese oyi kwesịrị ịdabere na nkọwa ndị akọwapụtara)

Normalization

Nnwale arụmọrụ (ihe eji arụ ọrụ, ihe mmetụta, ike ike, ire ụtọ, ire ọkụ, na flanging)

Na-agbanwe agbanwe

Ịcha tube

Nnwale na-adịghị emebi emebi (mgbapụta ọkụ ugbu a, ultrasonic, na magnetik flux)

Nnwale Hydrostatic

Nyocha ngwaahịa

Nkwakọ ngwaahịa

Ụlọ nkwakọba ihe

Ngwa Nrụpụta Ngwaahịa

Igwe na-akpacha ajị, igwe ịwa osisi, igwe ọkụ na-akpụ akpụ, onye na-ese ihe, igwe na-ese oyi nke ọma, igwe ọkụ na-ekpo ọkụ, na igwe na-agbazi

Ngwa Nleba Ngwaahịa

Ngwa ngwaahịa

Ngwugwu nke carbon steel ọkpọkọ enweghị nkebi

Okpu plastik etinyere n'akụkụ abụọ nke nsọtụ ọkpọkọ

Ekwesịrị ịzere ya site na eriri igwe na mmebi ụgbọ njem

Nchikota sians kwesịrị ịbụ otu na agbanwe agbanwe

Otu ngwugwu (ogbe) nke ọkpọkọ ígwè kwesịrị isi n'otu ọkụ ahụ pụta

The ígwè ọkpọkọ nwere otu ọkụ nọmba, otu ígwè gradethe otu nkọwa